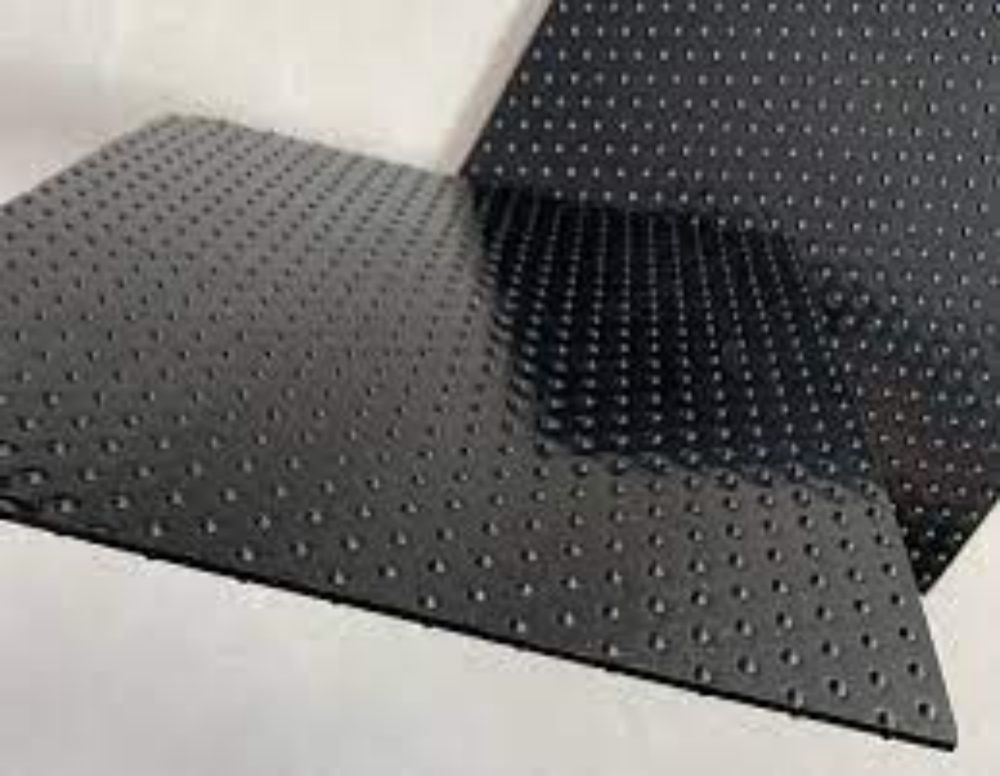

Anti-Seepage And Leak Proof Hdpe Geomembrane With Smooth

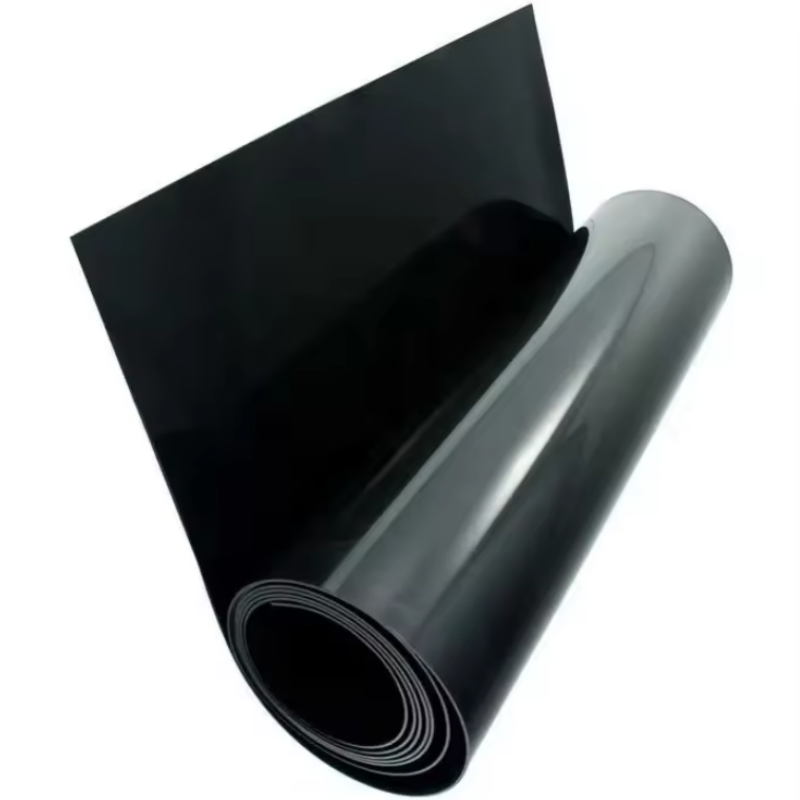

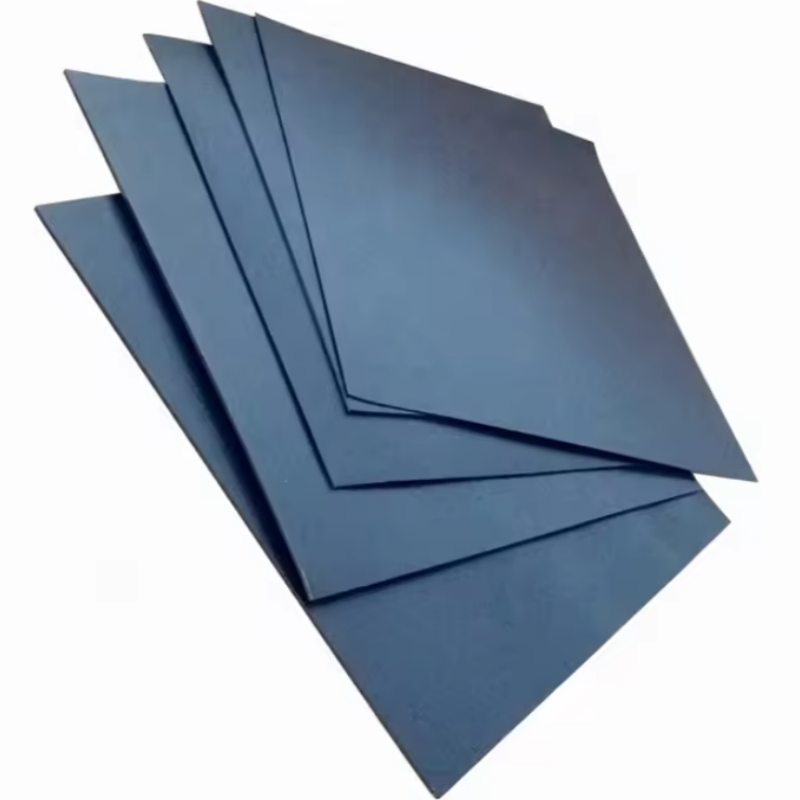

A Smooth Geomembrane is a type of impermeable geosynthetic material used widely in civil engineering and environmental protection projects. It is typically made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE) and features a smooth surface on both sides. This smooth surface provides low friction, making it easier to handle and install. The material is highly resistant to chemicals, UV radiation, punctures, and tears, ensuring long-term durability even in harsh environmental conditions.

Smooth geomembranes are used as liners in landfills, ponds, reservoirs, canals, and other containment applications, preventing the leakage of fluids or contaminants into the surrounding environment. Their flexibility, strength, and ease of deployment make them a popular choice for projects requiring reliable and cost-effective containment solutions.

1. Large friction coefficient – the small particles on the surface of the rough HDPE geomembrane increase the friction coefficient and the stability of the slope, thereby maximizing the available volume that the smooth HDPE membrane can carry.

2. High anti-seepage coefficient – the rough HDPE geomembrane has an anti-seepage effect that ordinary waterproof materials cannot match, and the water vapor permeability coefficient K<=1.0*10-13g.cm/c cm2.s.pa.

3. Chemical stability – the rough HDPE geomembrane has excellent chemical stability and is widely used in sewage treatment, chemical reaction tanks, and landfills. It is resistant to high and low temperatures, asphalt, oil tar, acid, alkali, salt and more than 80 strong acid and alkali chemical media corrosion.

4. Aging resistance – the rough HDPE geomembrane has excellent anti-aging, anti-ultraviolet, and anti-decomposition capabilities, can be used exposed, and the material service life is 50-70 years, providing a good material for environmental anti-seepage.

5. Resistance to plant roots–Rough surface HDPE geomembrane has the ability to resist puncture and can resist most plant roots.

6. High mechanical strength–Rough surface HDPE geomembrane has good mechanical strength, good elasticity and deformation ability, making it very suitable for expanding or shrinking base surface, which can effectively overcome the uneven settlement of the base surface, with a tensile strength of 28MP and an elongation of 700%.

7. Fast construction speed–Rough surface HDPE geomembrane has high flexibility, with a variety of specifications and laying forms to meet the anti-seepage requirements of different projects. It adopts hot melt welding, with high weld strength, and convenient and fast construction.

8. Environmental protection–The materials used in rough surface HDPE geomembrane are all pollution-free materials. The anti-seepage principle is ordinary physical change, and no harmful substances are produced. It is the best choice for aquaculture and drinking water pools.

1.Long life, anti-aging.

2.Good tensile strength, high elongation.

3.Good high/low temperature flexibility.

4.Easy to construct, no pollution.

5.Good anti-corrosive ability, can be used in special area.

6.Various colors are available.

Environmental protection, sanitation (such as domestic waste landfills, sewage treatment, toxic and hazardous waste treatment sites, dangerous goods warehouses, industrial waste, construction and blasting waste, etc.)

Water conservancy (such as anti-seepage, plugging, reinforcement of river, lake, reservoir and dam, anti-seepage of canals, vertical core walls, slope protection, etc.)

Municipal engineering (subway, underground engineering and rooftop water tanks of buildings, anti-seepage of rooftop gardens, lining of sewage pipes, etc.)

Garden (artificial lakes, ponds, pond bottom lining of golf courses, Slope protection, etc.)

Petrochemical (anti-seepage of oil tanks in chemical plants, refineries, gas stations, chemical reaction tanks, sedimentation tank linings, secondary linings, etc.)

Mining (anti-seepage of bottom linings of washing tanks, heap leaching tanks, ash dumps, dissolution tanks, sedimentation tanks, yards, tailings ponds, etc.)

Agriculture (anti-seepage of reservoirs, drinking water pools, water storage ponds, irrigation systems)

Aquaculture (lining of fish ponds, shrimp ponds, slope protection of sea cucumber pens, etc.)

Salt industry (crystallization pools in salt fields, brine pool covers, salt films, plastic films in salt pools)

The construction process for a geomembrane installation involves several critical steps to ensure proper placement and functionality. Here’s an overview of the typical process:

1. Site Preparation

Survey and Design: The first step is to conduct a thorough site survey to assess the terrain, soil conditions, and other environmental factors. Based on this, a detailed design of the geomembrane system is created, specifying the type, thickness, and layout of the geomembrane.

Clearing and Grading: The site is cleared of vegetation, debris, and any obstacles that could damage the geomembrane. The ground is then graded to achieve the desired slope and smoothness, ensuring that the surface is free of sharp objects or irregularities.

2. Subgrade Preparation

Compaction: The subgrade, or the foundation layer, is compacted to provide a stable and even base for the geomembrane. Proper compaction is essential to prevent settlement and ensure the longevity of the liner.

Installation of Geotextile (if needed): A layer of geotextile fabric may be placed over the subgrade to provide additional protection against punctures and to enhance the overall stability of the geomembrane.

3. Geomembrane Placement

Unrolling the Geomembrane: The geomembrane is delivered to the site in large rolls. These rolls are carefully unrolled and laid out according to the design specifications. This process is usually done in sections to minimize handling and reduce the risk of damage.

Positioning: The geomembrane sheets are positioned with enough overlap between adjacent panels to allow for seaming. Care is taken to ensure that the membrane lies flat without wrinkles or folds.

4. Seaming and Welding

Overlap and Alignment: Adjacent geomembrane panels are overlapped according to the manufacturer’s guidelines, typically by 100 to 150 mm (4 to 6 inches). Proper alignment is crucial to ensure the integrity of the seam.

Welding: Seams between panels are welded using either thermal fusion or chemical bonding, depending on the material of the geomembrane. The most common method is thermal fusion, which involves heating the edges of the panels and pressing them together to form a continuous, impermeable seam.

Inspection of Seams: Each seam is inspected visually and often tested using non-destructive methods such as air pressure testing or vacuum testing to ensure a strong, leak-proof bond.

5. Quality Control and Testing

Visual Inspection: A thorough visual inspection of the entire installation is conducted to check for any visible defects, such as tears, punctures, or unbonded seams.

Testing: Additional tests, such as destructive testing of sample seams, may be performed to verify the quality of the welds. Any detected defects are repaired immediately.

6. Anchoring and Backfilling

Anchoring: The edges of the geomembrane are securely anchored in trenches or other designated anchor points around the perimeter of the site. This prevents the membrane from shifting or being displaced by wind, water, or other forces.

Backfilling: In some cases, a protective layer of soil or other material may be placed over the geomembrane to protect it from physical damage and UV exposure, particularly in applications where the liner will be exposed for extended periods.

7. Final Inspection and Documentation

Final Inspection: A comprehensive final inspection is conducted to ensure that the geomembrane installation meets all design specifications and quality standards.

Documentation: Detailed records of the installation, including test results, material certifications, and as-built drawings, are compiled and submitted as part of the project documentation.

8. Project Close-Out

Site Cleanup: Any remaining debris or unused materials are removed from the site.

Final Approval: The project is reviewed and approved by the relevant authorities or the client, marking the completion of the geomembrane installation.

This process ensures that the geomembrane liner is installed correctly, providing effective containment and environmental protection for its intended application.

Equipment Of HDPE Geomembrane

Frequently Asked Question

We have professional brand machine production line and quality control center.Each batch of products will be sampled before package and there also is a final inspection before shipment.

Yes, we can offer free samples of some items for quality evaluation.

Yes.Our minimum order quantity is 200

Yes. Customized design orders are available.

General within 3-4 days.

T/T,PayPal,Western Union,Online Bank Payment.