Wholesale Injection Point Composite Geomembrane in Landfill

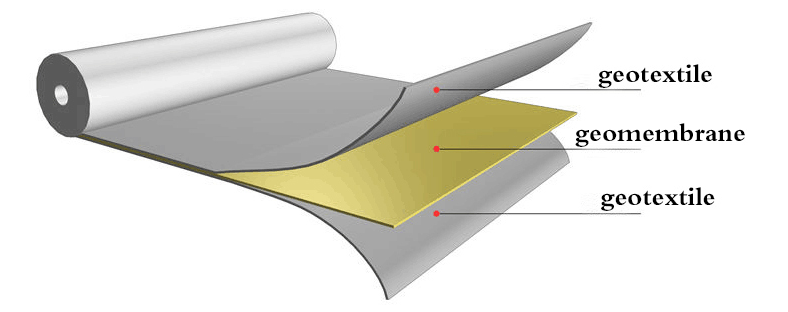

Composite geomembrane refers to a product made of geotextile as the base material and polyethylene, polyvinyl chloride, etc. as the membrane material. There are one cloth and one membrane, two cloths and one membrane, two membranes and one cloth, multiple cloths and multiple membranes, etc. The finished product is generally 6 meters wide and 50-100 meters long.

Composite geomembrane has good flexibility. In addition to the isolation, drainage, reinforcement, and protection functions of geotextile, it also has the closed and anti-seepage function of geomembrane. It is an ideal anti-seepage material and is widely used in water conservancy and transportation tunnel projects such as channels, levees, plain reservoirs, anti-seepage reinforcement of dangerous reservoirs, and anti-seepage of rockfill dams.

1. It integrates anti-seepage and drainage, has high strength, high friction coefficient, puncture resistance, aging resistance, acid and alkali resistance, and prevents soil erosion.

2. The composite geomembrane is made of filament geotextile or staple geotextile and PE geomembrane through thermal compounding, and has excellent properties of plane drainage and anti-seepage.

3. The composite geomembrane has high physical and mechanical performance indicators such as tensile resistance, tear resistance, and bursting resistance. The product has high strength, good elongation, large deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, and good anti-seepage performance.

4. Because it uses polymer materials and anti-aging agents are added in the production process, it can be used in unconventional temperature environments.

According to the structure and process, it can be divided into one cloth and one membrane, two cloths and one membrane, multiple cloths and multiple membranes, etc.

1. Film base fabric: 100-1000g/m2, film thickness: 0.1-1.5mm;

2. Two-cloth-one-film base fabric: 80-600g/m2, film thickness: 0.2-1.5mm;

3. One-cloth-two-film fabric: 100-1000g/square meter, film thickness: 0.1-0.8mm;

4. Fabrics with more than 4 pieces of cloth and film: 100-1000g/square meter, film thickness: 0.1-0.8mm;

Gram weight 200-1600g/m2, membrane thickness 0.1-1.5mm, width 3-6 meters, roll length 50-100 meters or customized on demand.

The service life of the composite geomembrane is mainly determined by whether the plastic film loses its anti-seepage and water-proofing effect. Generally, the polyethylene film with a thickness of 0.2m and stabilizer can work for 40 to 50 years under clear water conditions and 30 to 40 years under sewage conditions. Therefore, the service life of the composite geomembrane is sufficient to meet the service life requirements of the dam anti-seepage requirements.

Composite Geomembrane Application

Environmental protection and sanitation (landfills, sewage treatment pools);

Water conservancy projects (artificial lakes, canals, reservoirs);

Municipal construction projects (underground construction projects, roof gardens, warehouses);

Landscape and greening projects;

Petrochemical systems;

Aquaculture;

Anti-seepage in salt industry and other projects.

Geotextile is used as a protective layer for geomembrane to protect the anti-seepage layer from damage. In order to reduce ultraviolet radiation and increase anti-aging performance, it is better to use the embedding method for laying.

1. During construction, first use sand or clay with a smaller diameter to level the base surface, and then lay the geomembrane. The geomembrane should not be stretched too tight, and the parts buried in the soil at both ends are corrugated. Finally, a 10cm transition layer of fine sand or clay is laid on the laid geomembrane. 20-30cm blocks (or prefabricated concrete blocks) are laid as an anti-impact protective layer. During construction, efforts should be made to avoid stones hitting the geomembrane directly, and it is better to construct the protective layer while laying the membrane. The composite geomembrane should be connected to the surrounding structures with expansion bolts and steel plate strips for anchoring, and the connection parts should be coated with emulsified asphalt (2mm thick) for bonding to prevent leakage at that location.

2. The joint treatment of the composite geomembrane is a key process, which directly affects the anti-seepage effect. The general joint methods are: ① Overlap: The overlap width should be greater than 15cm; ② Hot welding: Suitable for slightly thicker geomembrane substrates, the weld overlap width should not be less than 5CM. (Gluing is not recommended, long-term water immersion is prone to debonding, and the anti-seepage effect is poor.)

3. According to years of practice, the thickness of the geomembrane should not be less than 0.25mm. Too thin may produce pores and is easily damaged during construction, reducing the anti-seepage effect. In the construction of geomembranes, special attention should be paid to ensure that the laying is not too tight, wrinkles should not be formed, and the splicing should be firm. Construction should be strictly carried out according to technical specifications, and the five quality control procedures of preparation, laying, splicing, inspection and backfilling should be well controlled.

Geomembrane Package

Equipment Of HDPE Geomembrane

Frequently Asked Question

We have professional brand machine production line and quality control center.Each batch of products will be sampled before package and there also is a final inspection before shipment.

Yes, we can offer free samples of some items for quality evaluation.

Yes.Our minimum order quantity is 200

Yes. Customized design orders are available.

General within 3-4 days.

T/T,PayPal,Western Union,Online Bank Payment.