0.75mm 1.5mm Fish farm Pond Liner Dam Liner HDPE Geomembrane

Geomembrane (also known as anti-seepage membrane), with a thickness of 0.2-3m, and a thickness of 0.8mm or more is also called waterproof board. It is a waterproof barrier material with high-quality polyethylene virgin resin as the basic raw material. The main components are 97.5% high-density polyethylene, about 2.5% carbon black, anti-aging agent, antioxidant, ultraviolet absorber, stabilizer and other auxiliary materials, with strong anti-seepage and isolation properties.

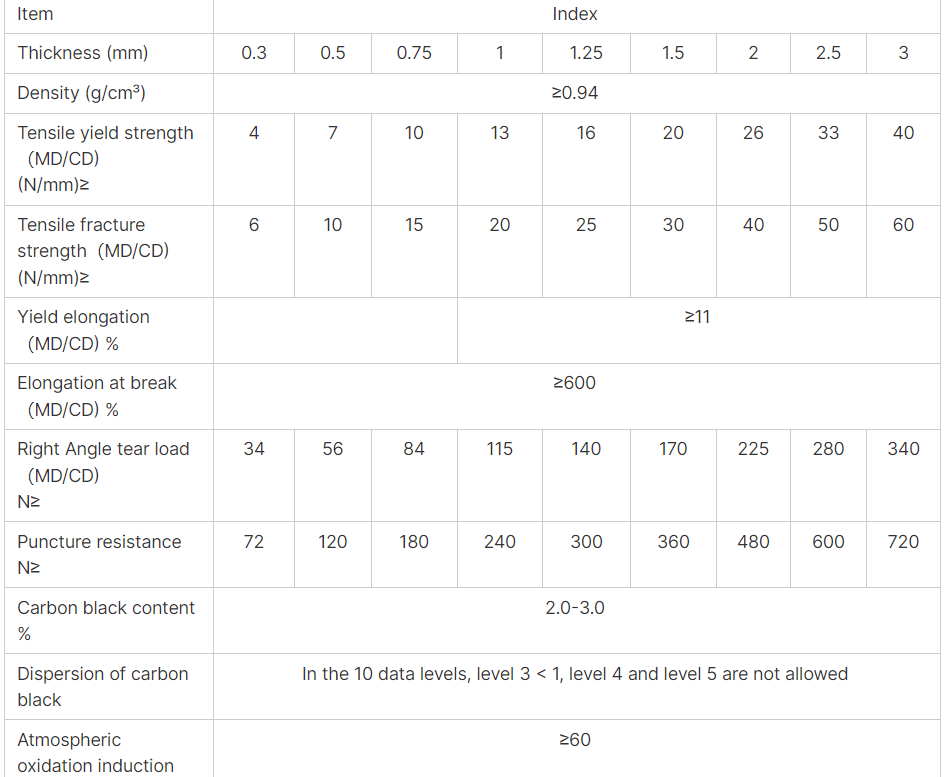

1. Geomembrane is a flexible waterproof material with a high anti-seepage coefficient (1×10-17cm/s);

2. Geomembrane has good heat resistance and cold resistance. Its use environment temperature is high temperature 110℃ and low temperature -70℃;

3. Geomembrane has good chemical stability and can resist corrosion from strong acids, alkalis and oils. It is a good anti-corrosion material;

4. Geomembrane has high tensile strength, which makes it have high tensile strength and can meet the needs of high-standard engineering projects;

5. Geomembrane has strong weather resistance and strong anti-aging performance. It can be exposed for a long time and maintain its original performance;

6. The overall performance of geomembrane is strong. Geomembrane has strong tensile strength and elongation at break, which enables geomembrane to be used under various harsh geological and climatic conditions. It has strong strain capacity to adapt to uneven geological settlement;

7. Geomembrane uses high-quality virgin plastic and carbon black particles without any preservatives. It has been used in my country to replace PVC as a raw material for food packaging bags and cling film.

Thickness 0.1mm-3mm, width 1-8 meters, roll length 50-100 meters, or customized according to customer needs.

1. It integrates anti-seepage and drainage functions, and has isolation and reinforcement functions.

2. High composite strength, high peel strength, and high puncture resistance.

3. Strong drainage capacity, high friction coefficient, and small linear expansion coefficient.

4. Good aging resistance, wide range of environmental temperature, and stable quality.

Geomembrane Application

1. Environmental protection and sanitation (such as domestic waste landfills, sewage treatment, toxic and hazardous waste treatment sites, dangerous goods warehouses, industrial waste, construction and blasting waste, etc.)

2. Water conservancy (such as anti-seepage, plugging, reinforcement of river, lake, reservoir and dam, anti-seepage of canals, vertical core walls, slope protection, etc.)

3. Municipal engineering (subway, underground engineering and rooftop reservoirs of buildings, anti-seepage of rooftop gardens, lining of sewage pipes, etc.)

4. Gardening (artificial lakes, ponds, pond bottom lining of golf courses, slope protection, etc. )

4. Petrochemical (anti-seepage of oil tanks in chemical plants, refineries, gas stations, linings of chemical reaction tanks, sedimentation tanks, secondary linings, etc.)

5. Mining (anti-seepage of bottom linings of washing tanks, heap leaching tanks, ash dumps, dissolution tanks, sedimentation tanks, yards, tailings ponds, etc.)

6. Agriculture (anti-seepage of reservoirs, drinking water pools, water storage ponds, irrigation systems)

7. Aquaculture (linings of fish ponds, shrimp ponds, slope protection of sea cucumber pens, etc.)

8. Salt industry (crystallization pools in salt fields, thatching of brine pools, salt films, plastic thatching films of salt pools)

1. It should extend from the bottom to the high position, not too tight, and 1.50% margin should be left to prepare for local sinking and stretching. Considering the actual situation of the project, the slope can be laid from top to bottom;

2. The longitudinal joints of two adjacent sections should not be on the same horizontal line, and should be staggered by more than 1m;

3. The longitudinal joints should be more than 1.50m away from the dam foot and the bend foot, and should be set on the plane;

4. First the slope and then the bottom of the field;

5. When laying the slope, the membrane expansion direction should be basically parallel to the maximum slope line.

6. When laying geomembranes, the minimum welds should be strived for, and raw materials should be saved as much as possible under the premise of ensuring quality. At the same time, it is also easy to ensure quality.

7. The overlap width of the joints between membranes is generally not less than 10cm, and the weld arrangement direction is usually parallel to the maximum slope, that is, arranged along the slope direction.

8. Usually in corners and deformed sections, the length of the joints should be shortened as much as possible. Except for special requirements, on slopes with a slope greater than 1:6, within 1.5 meters from the top slope or stress concentration area, try not to set welds.

9. Do not drag or pull the geomembrane during transportation to avoid being stabbed by sharp objects. During laying, avoid artificial wrinkles. When the temperature is low, try to tighten and lay it flat.

Geomembrane Package

Equipment Of HDPE Geomembrane

Frequently Asked Question

We have professional brand machine production line and quality control center.Each batch of products will be sampled before package and there also is a final inspection before shipment.

Yes, we can offer free samples of some items for quality evaluation.

Yes.Our minimum order quantity is 200

Yes. Customized design orders are available.

General within 3-4 days.

T/T,PayPal,Western Union,Online Bank Payment.