The geotextile is thicker, which can ensure the three-dimensional porosity of the geotextile, which is conducive to the realization of excellent hydraulic properties. The bursting strength of the geotextile has great advantages, especially suitable for retaining walls and embankment reinforcement. The indicators of geotextiles all exceed national standards and are excellent geotechnical reinforcement materials.

It is reported that as early as the early 1980s, foreign industrialized countries have widely used various specifications of glass fiber geotextiles in asphalt highway construction and asphalt pavement repair. The production technology and pavement construction operations of glass fiber geotextiles have been standardized, and have shown strong market competitiveness and good technical and economic effects.

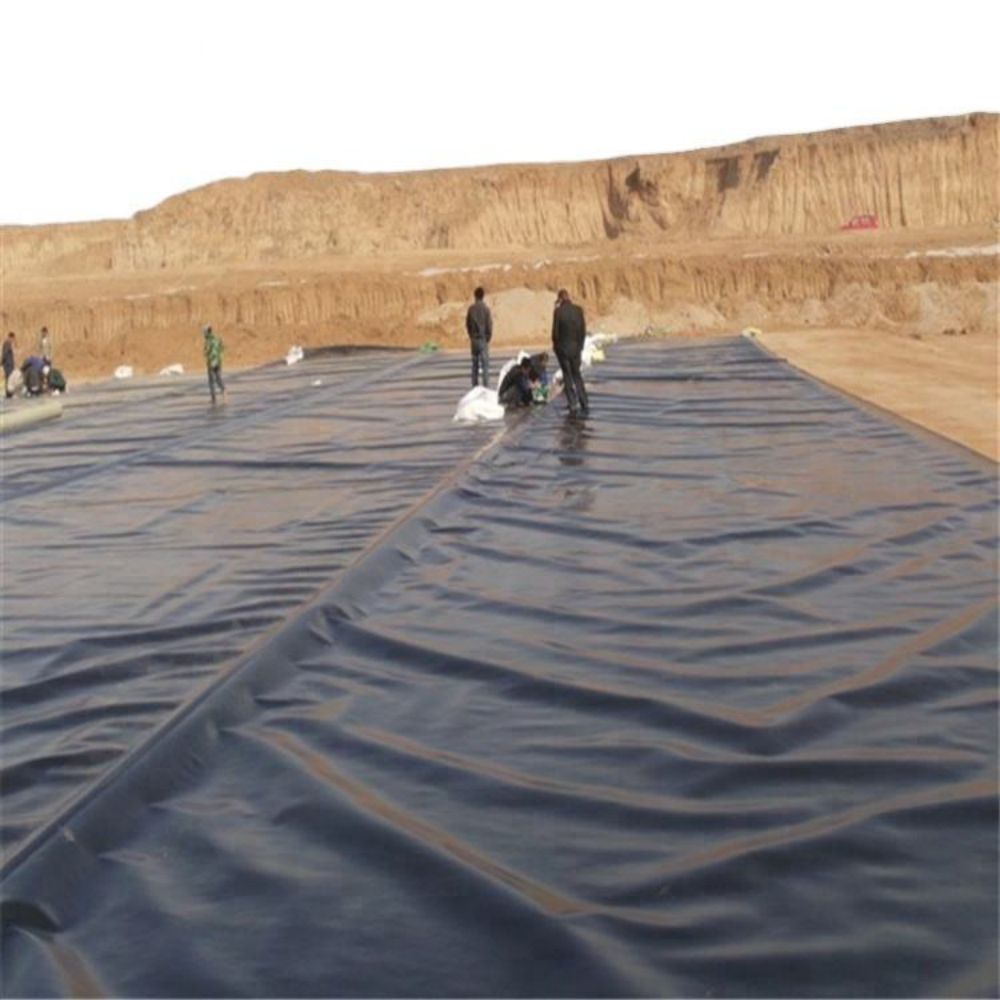

The anti-seepage effect of anti-seepage membranes has also been demonstrated in many cases. For example, the use of anti-seepage membranes in fish ponds and artificial lake projects has played an outstanding anti-seepage effect. So can the anti-seepage membrane be connected with the concrete wall of the pool?

One connection plan we have mastered is to embed the anti-seepage membrane connection lock in the concrete in advance before building the pool.

During construction, the edge of the anti-seepage membrane can be welded to the connection lock, and the anti-seepage effect is excellent. Another is to brush asphalt glue on the surface of the concrete, mix the inhomogeneity of the anti-seepage membrane with it, and then anchor it with edge strips and steel nails to make it firmly connected.

The width of polyester filament geotextile can reach 2-6.3 meters, and the gram weight can reach 100-800g/㎡. Such high performance characteristics make polyester filament geotextile widely used: Polyester filament geotextile is used for isolation of different materials: used between the roadbed and foundation of unpaved or paved roads and airport roads, used between geomembranes and sandy drainage layers, used between foundations and embankment soils, bear additional loads, used for additional loads, used between foundation soil and foundation piles, used under sidewalks, parking lots, and sports fields, and used between new and old asphalt layers; Polyester filament geotextile is used for reinforced soft foundation: used on unpaved soft foundations, used on airport roads, railways, landfills, and sports fields, to prevent the base soil from puncturing the geomembrane, and to prevent impurities or stone layers in the landfill from puncturing the geomembrane.

Polyester filament geotextile anti-filtration: under landfills with leakage, protect geonets, prevent soil particles from intruding, protect geocomposites, and prevent Prevent soil particles from invading; polyester filament geotextile is used for drainage under geomembrane, under sports field, and under railway ballast.