Landscaping Short Silk Geotextile Thick Non-Woven Fabric

Staple fiber needle-punched geotextile is made of polyester staple fiber as the main raw material, and is produced through processes such as opening, carding, ruffled, web laying, needle punching and spraying of water repellent.

High strength, due to the use of plastic fibers, it can maintain sufficient strength and elongation in dry and wet states.

Corrosion-resistant, it can resist corrosion for a long time in soil and water with different pH values.

Good water permeability, there are gaps between the fibers, so it has good water permeability.

Good anti-microbial properties, it is not damaged by microorganisms and insects.

Convenient construction, because the material is light and soft, it is convenient to transport, lay and construct.

Complete specifications: the width can reach 9 meters. It is the widest product in China, with a unit area mass of 100-1000g/m2

Light weight, low cost, corrosion resistance, with excellent properties such as anti-filtration, drainage, isolation, and reinforcement.

Common specifications: 100g/㎡-800g/㎡

Common width: 6m

Regular roll length: 50m (customizable)

Material: polyester staple fiber

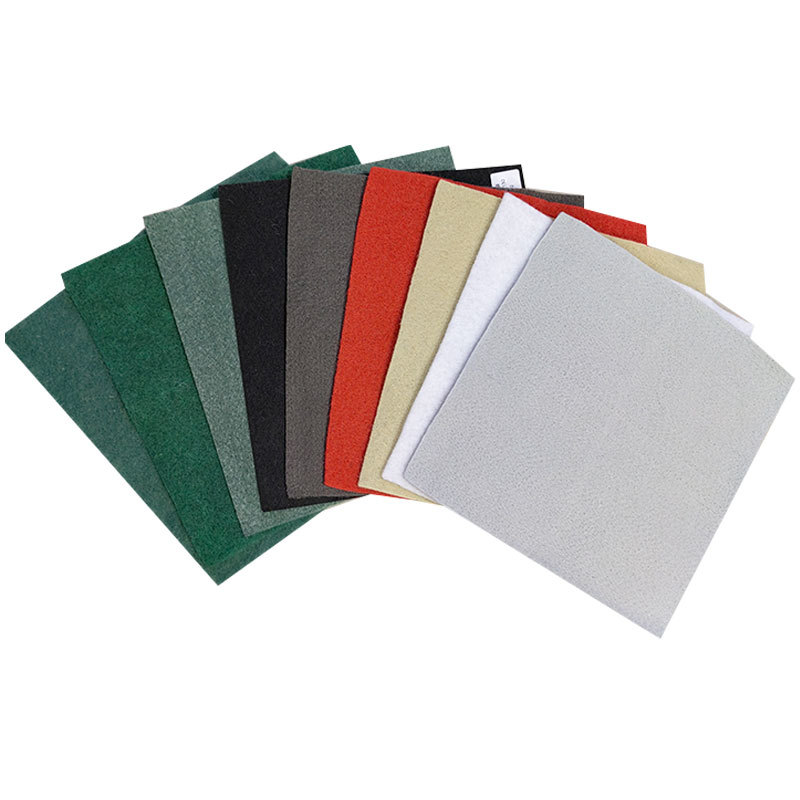

Color: white, black, green, camel (customizable)

Short Fiber Geotextile Application

Widely used in geotechnical engineering such as water conservancy, electricity, mines, roads and railways:

1. Filter materials for soil separation:

2. Drainage materials for reservoirs and mines, drainage materials for high-rise building foundations;

3. Anti-scouring materials for river embankments and slope protection;

4. Reinforcement materials for railway, highway and airport runway subgrades, and reinforcement materials for road construction in swamp areas;

5. Anti-frost and anti-freeze insulation materials:

6. Anti-cracking materials for asphalt pavement;

Spread by manual rolling, the surface of the fabric should be flat, and an appropriate margin for deformation should be left.

Basic requirements for laying geotextiles: the joints must intersect with the slope line; the distance between horizontal joints must be greater than 1.5m where it is balanced with the slope foot or where stress may exist.

On the slope, anchor one end of the geotextile, and then lower the roll to the slope to ensure that the geotextile remains taut.

All geotextiles must be pressed down with sandbags, which will be used during laying and retained until the upper layer of material is laid.

Short Fiber Geotextile Package

Production line Of Short Fiber Geotextile

Frequently Asked Question

We have professional brand machine production line and quality control center.Each batch of products will be sampled before package and there also is a final inspection before shipment.

Yes, we can offer free samples of some items for quality evaluation.

Yes.Our minimum order quantity is 200

Yes. Customized design orders are available.

General within 3-4 days.

T/T,PayPal,Western Union,Online Bank Payment.