The wider application of geotechnical materials in the mining industry can not only improve the recycling rate of mineral resources and the economic benefits of mines, but also greatly reduce the ecological environmental pollution problems in mines caused by factors such as leakage and drainage.

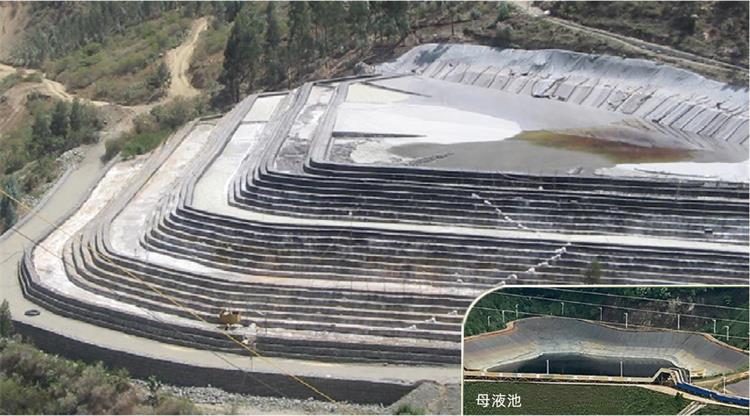

1. Heap leaching site and mother liquor pool

Heap leaching is widely used to extract gold, silver, copper and other metals. The anti-seepage of heap leaching sites and mother liquor pools is directly related to the leaching rate of precious metals and the yield of products. In addition, leakage will also bring the risk of environmental pollution. It is essential to choose an anti-seepage system composed of geotechnical materials.

2. Tailings Dam

Tailings ponds are important facilities for ore pollution control. The characteristics of phased construction and long-term use place extremely high demands on the anti-seepage and drainage systems of the reservoir bottom and dam body. Laying geotechnical materials in the tailings pond can prevent pollutants in the tailings from seepage and leakage due to long-term storage.

3. Mine restoration

After the mining operation, the overall environment is seriously damaged. Mine ecological restoration mainly includes the treatment of soil erosion, soil pollution, landslides, vegetation degradation, etc. caused by mining. Through treatment and restoration, the environment is restored to its original state and natural harmony is achieved. For example: mine restoration, slope restoration, ecological reclamation, and mine wasteland management.

4. Evaporation Pool

In the process of extracting lithium, sodium, magnesium, potassium and other metal elements from salt lake brine, geosynthetics play an important role in preventing seepage. Laying geomembranes and geotextiles can avoid the waste of brine resources and protect the ecological environment around brine channels and evaporation ponds.