Related Blogs

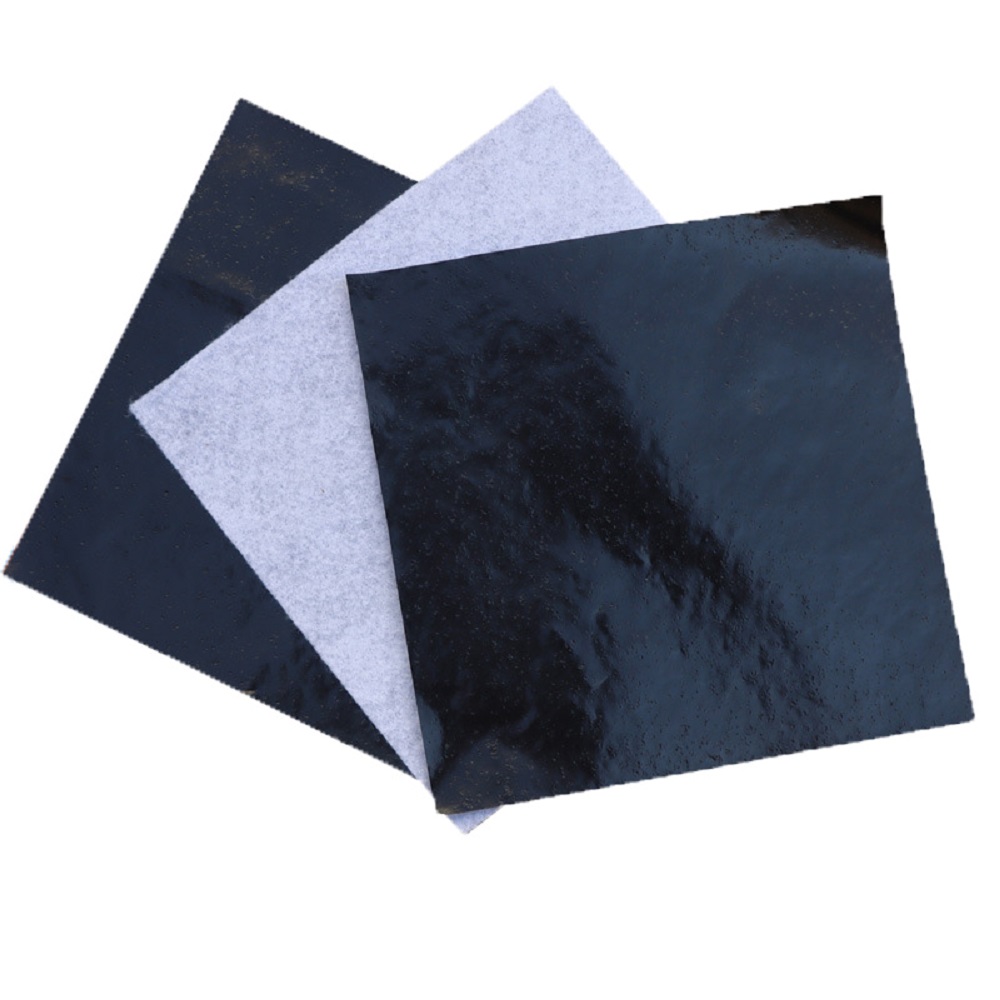

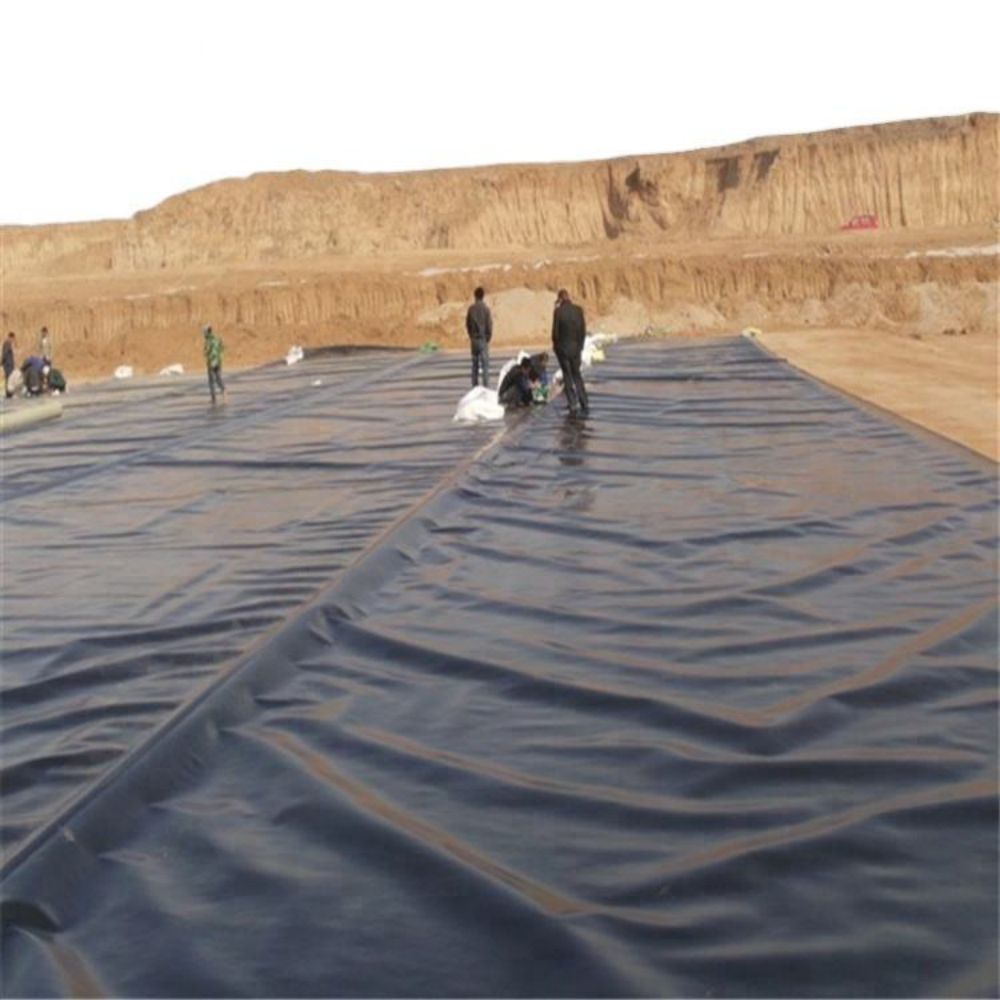

Focusing on the design, manufacturing, sales and after-sales service of geomembranes, geotextiles and GLC for more than 10 years, our products are sold all over the country and exported to more than 36 countries and regions.

How The Filament Geotextile Reduce Costs In Highway Construction

As an asphalt pavement reinforcement material, filament geotextile can prevent cracks in the pavement due to low-temperature shrinkage, change the structural stress distribution of the pavement, prevent the expansion of reflective cracks, and reduce the rolling marks of rutting.

Seven Advantage of Geotextile Fabric On Modern Construction

In the ever-evolving world of construction and civil engineering, geotextile fabrics have emerged as indispensable tools that offer a wide array of benefits.

What Is the Production Progress of Geotextile

Construction is a big project, during which the ground will be constantly polluted by debris falling from high places. However, after we cover the ground with geotextile, we can remove it and the ground is still clean as before, which saves the step of cleaning the ground. This also brings convenience to our work, so let’s take a look at the production process of this geotextile.